1. Material Structure and Interfacial Engineering

1.1 Core-Shell Structure and Bonding Mechanism

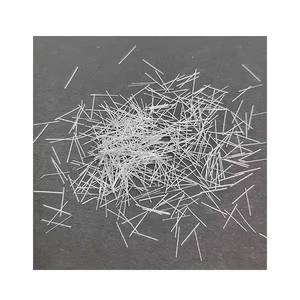

(Copper-Coated Steel Fibers)

Copper-coated steel fibers (CCSF) are composite filaments consisting of a high-strength steel core wrapped up by a conductive copper layer, forming a metallurgically bound core-shell architecture.

The steel core, normally low-carbon or stainless-steel, supplies mechanical effectiveness with tensile toughness surpassing 2000 MPa, while the copper layer– usually 2– 10% of the total diameter– conveys superb electric and thermal conductivity.

The user interface in between steel and copper is vital for performance; it is crafted through electroplating, electroless deposition, or cladding processes to ensure solid adhesion and marginal interdiffusion under functional stress and anxieties.

Electroplating is one of the most usual technique, supplying accurate density control and uniform protection on continual steel filaments attracted with copper sulfate bathrooms.

Proper surface area pretreatment of the steel, including cleansing, pickling, and activation, makes sure optimal nucleation and bonding of copper crystals, protecting against delamination during subsequent processing or service.

With time and at elevated temperatures, interdiffusion can develop brittle iron-copper intermetallic stages at the interface, which may compromise versatility and long-lasting dependability– a challenge alleviated by diffusion barriers or fast handling.

1.2 Physical and Practical Properties

CCSFs combine the very best features of both basic steels: the high flexible modulus and fatigue resistance of steel with the superior conductivity and oxidation resistance of copper.

Electrical conductivity commonly ranges from 15% to 40% of International Annealed Copper Criterion (IACS), relying on coating thickness and pureness, making CCSF significantly a lot more conductive than pure steel fibers (

Cabr-Concrete is a supplier under TRUNNANO of Calcium Aluminate Cement with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for microsteel, please feel free to contact us and send an inquiry.

Tags: micro steel fiber,steel fiber,steel fiber reinforced concrete

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us