1. Essential Roles and Useful Goals in Concrete Innovation

1.1 The Function and Mechanism of Concrete Foaming Representatives

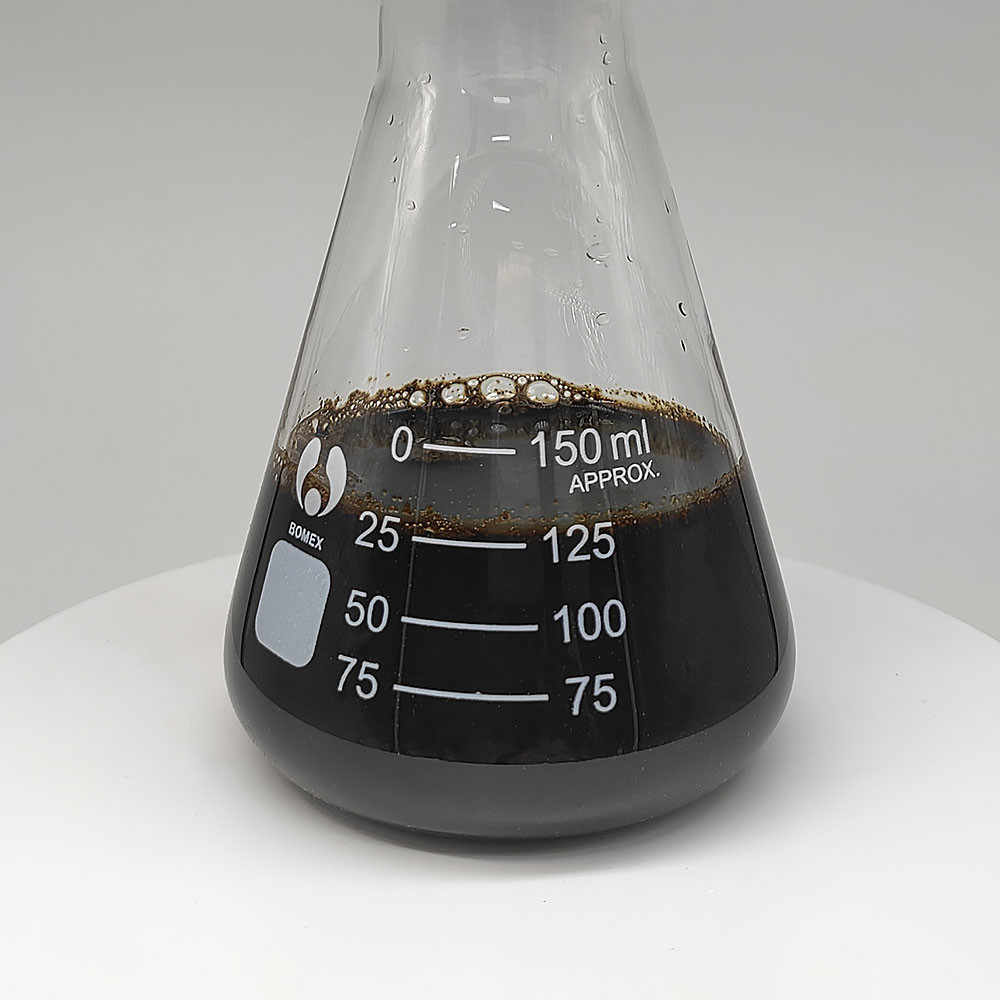

(Concrete foaming agent)

Concrete foaming representatives are specialized chemical admixtures designed to intentionally present and maintain a controlled volume of air bubbles within the fresh concrete matrix.

These representatives operate by reducing the surface stress of the mixing water, making it possible for the development of penalty, uniformly dispersed air spaces during mechanical frustration or mixing.

The key objective is to produce mobile concrete or lightweight concrete, where the entrained air bubbles significantly reduce the general density of the solidified product while preserving sufficient architectural integrity.

Foaming agents are generally based upon protein-derived surfactants (such as hydrolyzed keratin from pet results) or synthetic surfactants (consisting of alkyl sulfonates, ethoxylated alcohols, or fat derivatives), each offering distinctive bubble stability and foam structure attributes.

The produced foam has to be steady adequate to survive the blending, pumping, and initial setup phases without extreme coalescence or collapse, ensuring an uniform mobile framework in the end product.

This engineered porosity boosts thermal insulation, decreases dead load, and boosts fire resistance, making foamed concrete suitable for applications such as shielding flooring screeds, gap dental filling, and prefabricated lightweight panels.

1.2 The Objective and System of Concrete Defoamers

In contrast, concrete defoamers (also referred to as anti-foaming representatives) are created to remove or reduce unwanted entrapped air within the concrete mix.

Throughout mixing, transportation, and positioning, air can come to be unintentionally allured in the cement paste as a result of agitation, especially in very fluid or self-consolidating concrete (SCC) systems with high superplasticizer web content.

These entrapped air bubbles are usually irregular in dimension, badly dispersed, and damaging to the mechanical and visual buildings of the hard concrete.

Defoamers function by destabilizing air bubbles at the air-liquid user interface, advertising coalescence and tear of the thin fluid films bordering the bubbles.

( Concrete foaming agent)

They are commonly made up of insoluble oils (such as mineral or veggie oils), siloxane-based polymers (e.g., polydimethylsiloxane), or solid fragments like hydrophobic silica, which penetrate the bubble movie and increase drain and collapse.

By reducing air web content– normally from problematic degrees over 5% to 1– 2%– defoamers enhance compressive strength, improve surface area finish, and increase toughness by lessening leaks in the structure and potential freeze-thaw susceptability.

2. Chemical Make-up and Interfacial Habits

2.1 Molecular Style of Foaming Brokers

The efficiency of a concrete foaming representative is very closely connected to its molecular structure and interfacial task.

Protein-based lathering agents count on long-chain polypeptides that unfold at the air-water user interface, creating viscoelastic films that stand up to tear and supply mechanical toughness to the bubble wall surfaces.

These all-natural surfactants generate reasonably large but secure bubbles with great persistence, making them suitable for architectural light-weight concrete.

Artificial frothing representatives, on the other hand, deal higher consistency and are less sensitive to variants in water chemistry or temperature.

They create smaller, a lot more uniform bubbles because of their lower surface stress and faster adsorption kinetics, leading to finer pore structures and boosted thermal efficiency.

The vital micelle concentration (CMC) and hydrophilic-lipophilic balance (HLB) of the surfactant identify its performance in foam generation and stability under shear and cementitious alkalinity.

2.2 Molecular Architecture of Defoamers

Defoamers run via a basically different mechanism, relying on immiscibility and interfacial incompatibility.

Silicone-based defoamers, particularly polydimethylsiloxane (PDMS), are highly effective due to their exceptionally low surface area tension (~ 20– 25 mN/m), which allows them to spread out quickly throughout the surface of air bubbles.

When a defoamer droplet get in touches with a bubble film, it develops a “bridge” between the two surface areas of the film, inducing dewetting and rupture.

Oil-based defoamers operate likewise however are less reliable in very fluid blends where quick dispersion can weaken their activity.

Hybrid defoamers including hydrophobic particles improve performance by offering nucleation sites for bubble coalescence.

Unlike foaming agents, defoamers should be moderately soluble to stay energetic at the interface without being incorporated into micelles or dissolved right into the bulk phase.

3. Effect on Fresh and Hardened Concrete Residence

3.1 Impact of Foaming Professionals on Concrete Performance

The calculated introduction of air using foaming representatives transforms the physical nature of concrete, shifting it from a thick composite to a porous, light-weight material.

Thickness can be minimized from a regular 2400 kg/m six to as low as 400– 800 kg/m SIX, depending upon foam volume and stability.

This reduction straight associates with lower thermal conductivity, making foamed concrete a reliable protecting product with U-values appropriate for developing envelopes.

However, the increased porosity also leads to a decline in compressive stamina, demanding cautious dose control and frequently the inclusion of supplemental cementitious materials (SCMs) like fly ash or silica fume to boost pore wall surface stamina.

Workability is usually high as a result of the lubricating result of bubbles, but segregation can occur if foam security is inadequate.

3.2 Influence of Defoamers on Concrete Efficiency

Defoamers boost the quality of conventional and high-performance concrete by getting rid of problems brought on by entrapped air.

Extreme air gaps work as stress and anxiety concentrators and reduce the reliable load-bearing cross-section, bring about lower compressive and flexural toughness.

By reducing these voids, defoamers can enhance compressive stamina by 10– 20%, especially in high-strength blends where every volume percent of air matters.

They also enhance surface area quality by protecting against pitting, insect openings, and honeycombing, which is important in building concrete and form-facing applications.

In impenetrable frameworks such as water tanks or cellars, lowered porosity boosts resistance to chloride access and carbonation, expanding life span.

4. Application Contexts and Compatibility Factors To Consider

4.1 Typical Usage Instances for Foaming Brokers

Foaming agents are crucial in the production of mobile concrete utilized in thermal insulation layers, roofing decks, and precast light-weight blocks.

They are additionally employed in geotechnical applications such as trench backfilling and gap stablizing, where low density avoids overloading of underlying soils.

In fire-rated assemblies, the shielding buildings of foamed concrete supply passive fire protection for structural aspects.

The success of these applications depends on exact foam generation tools, stable foaming agents, and appropriate mixing procedures to ensure uniform air circulation.

4.2 Normal Use Instances for Defoamers

Defoamers are commonly utilized in self-consolidating concrete (SCC), where high fluidness and superplasticizer material boost the risk of air entrapment.

They are additionally essential in precast and architectural concrete, where surface coating is critical, and in underwater concrete positioning, where entraped air can endanger bond and resilience.

Defoamers are frequently added in little does (0.01– 0.1% by weight of cement) and should work with other admixtures, particularly polycarboxylate ethers (PCEs), to stay clear of damaging interactions.

To conclude, concrete frothing representatives and defoamers represent 2 opposing yet equally crucial methods in air administration within cementitious systems.

While frothing agents intentionally present air to attain lightweight and protecting homes, defoamers get rid of undesirable air to boost toughness and surface area quality.

Understanding their distinct chemistries, devices, and impacts allows designers and manufacturers to optimize concrete efficiency for a vast array of architectural, functional, and aesthetic requirements.

Supplier

Cabr-Concrete is a supplier of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality Concrete Admixture, please feel free to contact us and send an inquiry.

Tags: concrete foaming agent,concrete foaming agent price,foaming agent for concrete

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us